Title

Keywords

Year

est.

restoration guidelines

"As much as necessary, as little as possible."

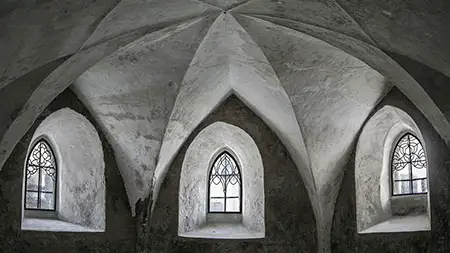

In contrast to conventional repairs, different paradigms apply to the conservation of leaded glass that is classified as historically significant. Since the majority of existing leaded windows are located in listed architecture, the field of conservation in connection with leaded glass plays a central role.

The "Richtlinien für Konservierung und Restaurierung von Glasmalereien" , which were written in Nuremberg in 2004 by the Corpus Vitrearum Austria, offer a compact guideline for this.

The following five guidelines are to be adhered to for any intervention in the conservation of historical monuments:

care: Greatest possible protection of the original substance

conservation: Highest possible protection against expected future damage

restoration: The closest possible approximation to the original appearance

reversibility: Consideration of the possibility of reversing applied measures

documentation: Exact description of the condition of the original and specification of the measures applied. (download example .pdf)

Since every restoration measure brings new challenges, it is difficult to formulate universally valid solutions. Therefore, decisions must always be made on the basis of science and practice as well as in an interdisciplinary exchange with the heritage office and the commissioning parties.

damage patterns

Glass Breakage

Probably the most obvious type of damage to leaded glass is the breaking of pieces of glass. Roughly speaking, glass breakage can be divided into four degrees:

-single crack

-multiple cracks

-flaw

-multiple cracks with a flaw

Especially in the field of monument conservation, not every breakage requires the replacement of the original piece of glass. On the contrary, in the case of simple cracks where the piece of glass does not run the risk of falling out, it is sometimes not necessary to take any measures at all from a conservation point of view.

There are a number of possible procedures when intervening in the case of broken glass:

Replacement of the glass

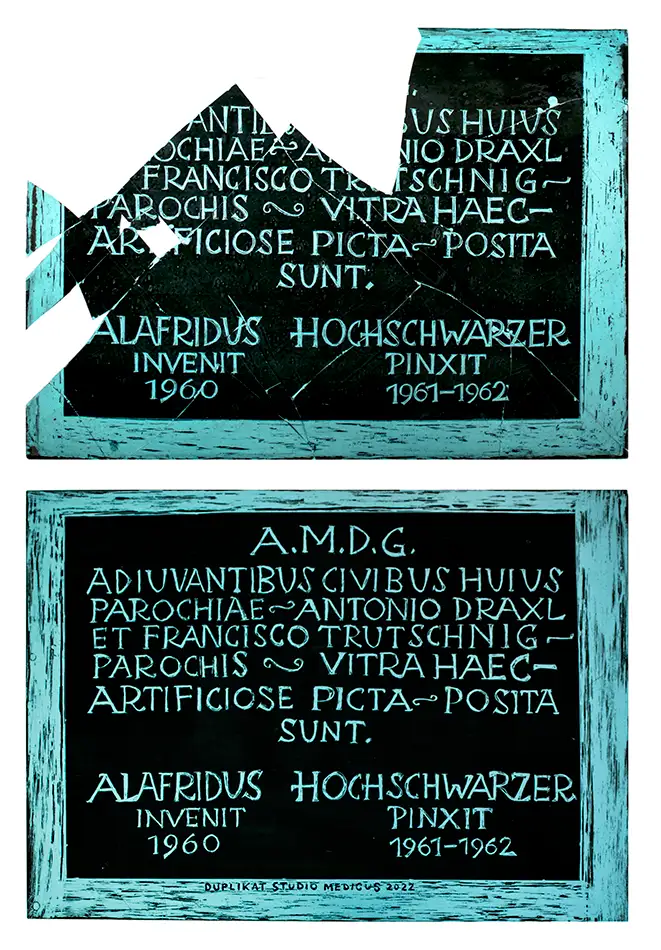

In some cases it may make sense to duplicate the glass. Individual broken pieces of leaded glass can be removed from the lead mesh and the new piece reinstalled.

Special care must be taken to ensure that the correct type and colour of glass is used. If there is a layer of paint (usually enamel paint) on the original glass, this must be replicated. To make it clear that it is a duplicate, this must be noted on the glass piece. In certain cases it is even useful to make the duplicate in such a way that it stands out stylistically from the rest of the painting and is thus easily recognisable as a replica.

Adhesive lead

In some cases, the use of so-called adhesive lead is useful for gluing over and securing cracks. Since it is visible as a black line in the view through the window, like the rest of the lead net, its applicability remains limited. Adhesive lead can be used in the installed state.

Adhesive resins

It is precisely the reversibility, the long durability, the good adhesion to glass and the high transparency of adhesive resins that make them suitable for restoration.The adhesives can be used very well for bonding broken pieces of glass both when the glass is installed and in the workshop.The epoxy resin Araldite 2020 or HXTAL NYL-1 is often used for this purpose.

Smaller defects of glass pieces that are particularly worth preserving can be filled with the same resin and then painted with a mixture of acrylic resin Paraloid B 72 and colour pigments.This technique makes it possible to repair the glass piece while preserving all the existing shards.

Tiffany technique

Developed at the end of the 19th century, this technique is suitable for reconnecting broken pieces. The technique provides a more stable and slightly less visible bond than adhesive lead but is much more visible compared to bonding with resins.

The affected piece of glass must be removed for use.

As with adhesive resins, the technique allows a lost part of a piece of glass to be completed and connected to the original without having to replace the entire piece.

Bulges

Bulging and sagging can have a variety of causes. They frequently occur in leaded glazing in doors or openable windows.

In addition to bulging due to direct mechanical effects, damaged lead rods, detached or defective reinforcing bars, missing putty between glass and lead or certain lead line guides also reduce the stability of the lead light and can lead to sagging.

Measures:

After removing the affected panels, bulges can usually be carefully bent back on the workshop table. To prevent future sagging, it is helpful to renew the cement and to re-solder torn-off wind bar clamps and solder joints. If the lead field has too few reinforcing bars for its size and structure, additional ones can be added to stabilise it.

Lead Damage

For a long time, lead was neglected in connection with listed stained glass. As a result, leaded stained glass was often completely dismantled and re-leaded for restoration, whereby the original lead network was completely lost. Original lead from the Middle Ages is therefore hardly preserved.

In the meantime, lead strips have been recognised as an integral part of the craft piece and as historical evidence of the respective manufacturing technique. The H-sections that hold the glass pieces together are therefore preserved as best as possible, which is possible in many cases.

Cracked solder joints

Aged or permanently mechanically stressed lead often shows cracks. In many cases, these can be re-soldered after removing the patina, thus achieving a noticeable stabilisation of the lead field.

Lead corrosion

Due to the reaction with oxygen, lead forms a protective layer on the surface within a short time, which prevents further oxidation. As a rule, this layer provides sufficient protection against the decomposition of the lead. However, acids released from adjacent linseed oil putty, wood or plaster can decompose the lead. This produces toxic white lead oxide dust. Since this dust can easily enter the respiratory tract, it is necessary to wear a protective mask.

Detachment of Paint

Despite the extremely good durability of enamel paints, they can be affected by environmental influences or incorrect processing.

For example, layers of paint can lose their stable base due to glass corrosion and begin to peel off. But improper cleaning or restoration measures can also lead to the loss or detachment of stained glass. Furthermore, incorrect baking of enamel paints can prevent them from forming a stable bond with the glass surface.

Measures:

Painting layers that are threatening to peel off acutely can be effectively protected from loss by infiltrating them with the acrylic resin Paraloid B 72. In the longer term, endangered glass paintings must be shielded from harmful environmental factors such as water, exhaust fumes, acid rain, hail or stone throwing, above all by protective glazing.

Surface Changes and Deposits

Especially with medieval leaded glass, the issue of altered glass surfaces is very multi-layered and complex. Over the course of several centuries, leaded glass was exposed to many different external influences that affected the glass surfaces in various ways.

In addition, the chemical composition of the glass can vary greatly depending on the time, place and technique of manufacture, which is why the possibilities for surface changes are so varied.

Due to limited technological possibilities, attempts were made for a long time to keep the melting point of glass low by using a relatively large amount of flux (potash). Therefore, these forest and potash glasses have a lower proportion of silicon oxide, which makes them more susceptible to a chemical change of their surface.

Glass corrosion, pitting and weathered glass

Above all, sulphur dioxide, which is contained among other things in acid rain, can initially lead to corrosion (pitting) on the outside of the glass in certain places. In combination with water, this can lead to alkaline components of the glass - which is covered with very fine cracks - being dissolved out on the surface and deposited on the glass surface as whitish, powdery corrosion products. These water-attracting deposits in turn promote the corrosion process. Last but not least, corrosion of the glass surface leads to detachment of the painting layer.

Measures:

Here, a rough distinction can be made between mechanical and chemical interventions. Scalpels or glass fibre pens are used as mechanical tools, which are often more suitable than chemical methods because they can be used selectively and are easy to dose. Basically, however, the type and intensity of the intervention must be reassessed from case to case.

The field of chemical intervention is controversial because of the risk of major irreversible damage. With regard to the removal of weathered glass, however, there are promising results with ion exchangers.

Browning

In certain medieval glasses, the formation of weathered glass leads to another undesirable effect: the manganese used in the glass - both for colouring and decolouring - comes into direct contact with oxygen and begins to oxidise. If the manganese is heavily browned, hardly any light can pass through the glass.

Measures:

In the past, successful attempts were made to lighten browned windows with the very toxic hydrazine. Hydrazine lowers the oxidation level of the manganese, but is not able to dissolve it from the gel layer of the glass, which is why browning is to be expected again after treatment. The only way to remove the manganese was with formic acid, but this can severely attack the glass and is therefore too crude an intervention. Therefore, after treatment with hydrazine, it was more common to seal the gel layer of the glass with so-called Ormocer and thus prevent renewed oxidation.

Since all these methods are ultimately crude and partly irreversible interventions, they are not used in most cases.

Microorganisms and fungi

For a long time, little research was done on the influence of microorganisms and fungi on the glass surfaces of stained glass, even though the phenomenon has long been known from optical devices such as camera lenses. Fungal metabolites - such as acidic ones - often cause irreparable damage to the surface.

Although fungi cannot feed on the glass itself, they can feed on a wide variety of deposits such as traces of putty or oil as well as certain organic cold paints or cleaning agents.

In addition to certain climatic conditions, such as heat and high humidity, the porous and rough surface of weathered glass and glass corrosion favours the development of fungal growth.

Measures:

In addition to changing the climatic conditions, there have been investigations into making the glass surfaces uninhabitable for fungi with coatings containing copper. Furthermore, organic substances can also be destroyed or removed by means of UV light and disinfectants. Which measure can be applied must be put up for discussion when drawing up the restoration concept.

constructive details

Types of Glass

A wide variety of glasses are used in the fields of restoration, conservation and art glazing. Here are the most commonly used:

Genuine antique glass

Hand-blown glass is the most commonly used material for coloured leaded glass and church windows. It is characterised by its impressive richness of colour, bubble inclusions and irregular surface.

The glass is still largely produced today using the same techniques as in the Middle Ages.

Cathedral glass

Like many other ornamental glasses, this glass is also produced by the rolling process. By pouring it onto the rolling mill, it takes on the characteristic pattern of the base. In contrast to its time of origin, today it is produced in an industrial process. The glass can be used in many different ways.

Restoration glass

Restoration glass is a group of colourless glasses that are mainly used as window panes in listed buildings. The glass is characterised by varying degrees of unevenness.

Crown glass

Genuine crown glass is mouth-blown - similar to genuine antique glass. However, there are also industrial products that are modelled on the look of round bull's-eye panes. They are mainly used in connection with lead glazing.

Float glass

Float glass is by far the most commonly used type of glass today. By producing it on a tin bath, it is possible to produce large formats with a perfectly smooth surface. Its widespread use began in the mid-20th century and has fundamentally changed the possible uses of glass, pushing back many other types of glass. In the context of conservation, it is used for protective glazing, for example.

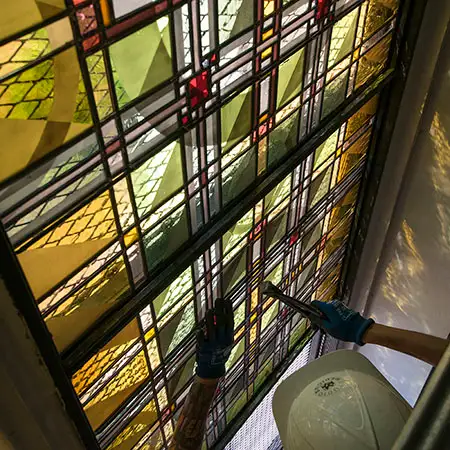

Protective Glazing

Protective glazing

The subject of protective glazing is particularly relevant in the context of historic stained glass. There are countless examples from the recent past of protective glazing that have caused damage rather than contributing to conservation. Unproven constructions led to the formation of condensation and heat accumulation or to the deposition of impurities as well as the formation of microorganisms and fungi in the inaccessible space between the panes. In addition to the protection of the stained glass, some attempts were made to make churches heatable with double or triple glazing. Apart from the many complications caused by these interventions, it also turned out that complete heating is not sensible due to the great room heights and the short use phase of churches.

Isothermal glazing

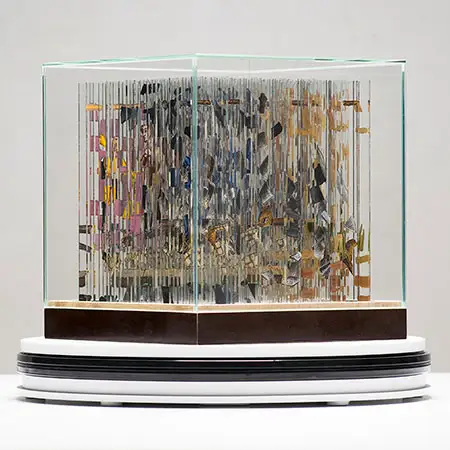

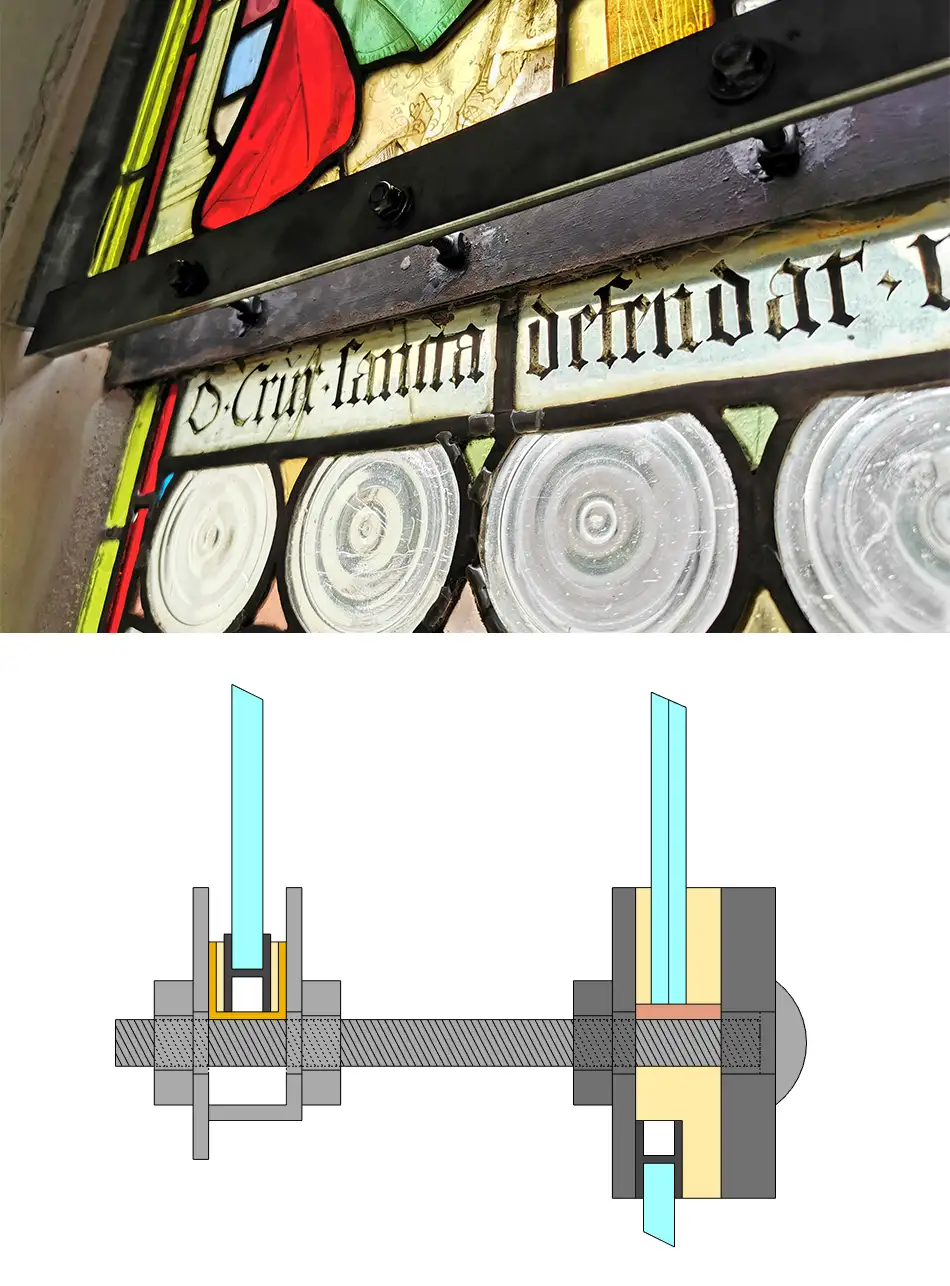

Through intensive research and testing of different protective glazing systems, so-called isothermal glazing has now become established. With this type of protective glazing, existing lead fields are removed and replaced by a safety glass.The historic window is moved inwards into the church interior.Thus it is protected from external influences such as exhaust fumes, acid rain, stone throwing, hail or strong temperature fluctuations and sits well ventilated in the interior. Good rear ventilation is essential to prevent the formation of condensation, microorganisms or fungi on the glass surface.

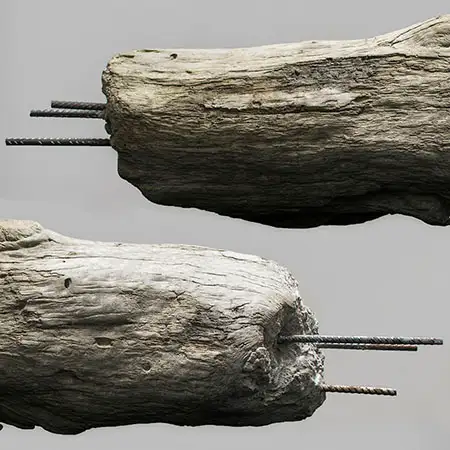

This technique also has the advantage that it represents a minor intervention in the historic substance: Leaded panels are carefully removed from the reveal, restored in the workshop and then mounted in the new holder in such a way that any reassembly can be carried out without any problems. The brackets required for this are attached to the existing crossbars by threaded rods. In an equally gentle manner, the front glasses are mounted in the original rebate of the lead field, usually with lime plaster and putty.

Cementing

In connection with historical leaded glass, putty is the most commonly used sealant.

On the one hand, it is found in the small gaps between lead rods and pieces of glass, and on the other hand, it is used to seal between glass and frame or crossbar

Due to oxidation, putty hardens completely in the air, becomes brittle and can break out. In addition to the resulting leaks, lead frames can lose their stability due to the lack of putty and sag or buckle. This causes solder joints to crack and eventually leads to glass breakage.

While putty is applied over the entire surface of the back of the window and brushed into the lead strips when making new lead glass, this technique is not suitable for historic glazing in some cases. On the one hand, painting layers and glass surfaces can be directly damaged by the mechanical action, and on the other hand, organic residues of the putty can attack the historic substance long after the measures have been taken.

How lost putty can be reintroduced into the lead fields must be decided on a case-by-case basis. In addition to the question of whether and on which side there is a layer of paint, the age and condition of the glass, for example, must be assessed.

Tilt Window

Durable and easy-to-use tilt windows for cross-ventilation of church rooms are an important device for influencing the indoor climate. For example, this proven design allows the window to be either opened or closed at a great height with the help of a rope.

Working Techniques

Leadlighting

The technique of lead glazing has existed since the Middle Ages and has survived to this day. Its use is not limited to church windows, it can also be excellently applied in contemporary contexts. The often dusty character is mainly due to its history. Especially through the reduced use of painting and the use of light glass colours, the lead glazing technique can be easily transferred into today's world and at the same time guarantee a standard-compliant processing.

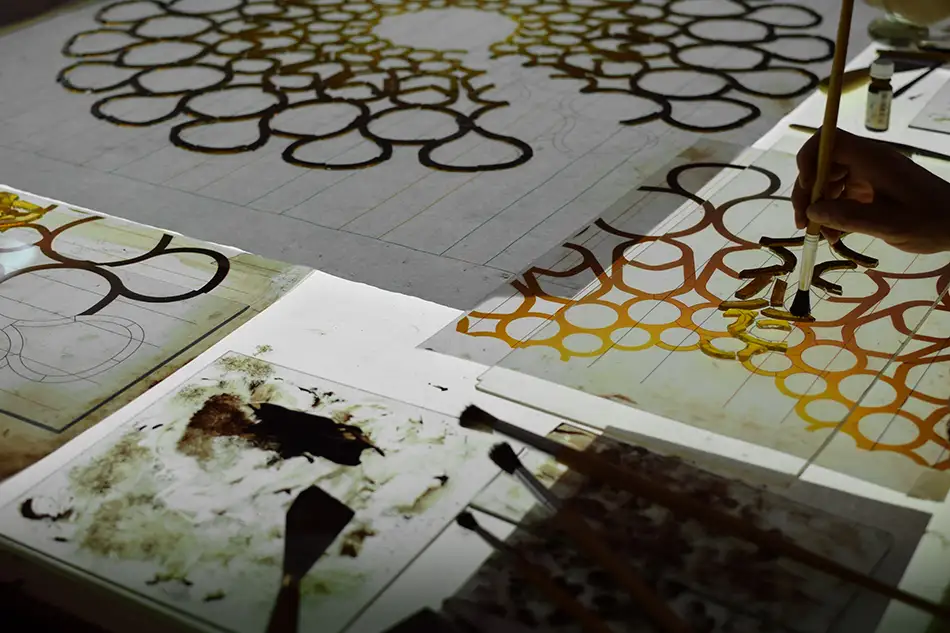

Painting

In many ways, stained glass is an exceptional painting technique. Because enamel colours are fired and bond with the glass surface, they are extremely durable compared to other colours. However, some colours change their optical appearance through firing, which requires samples, experience and very specific processing methods. Stained glass can be used in a wide variety of ways, from planar, bright and abstract to contoured, strong and figurative.

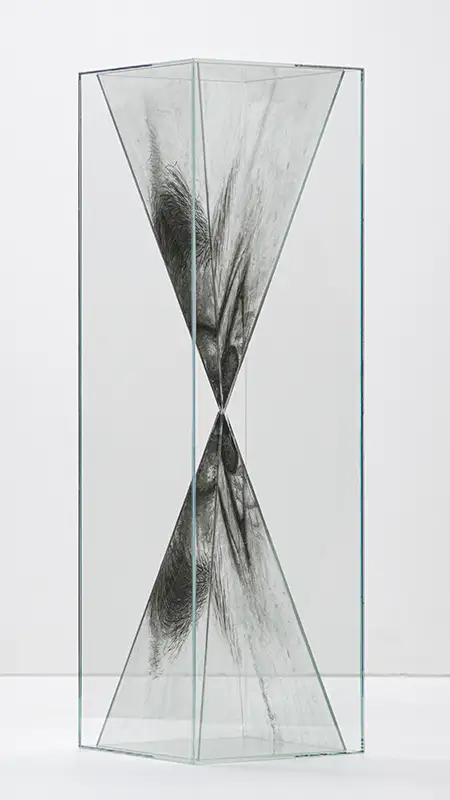

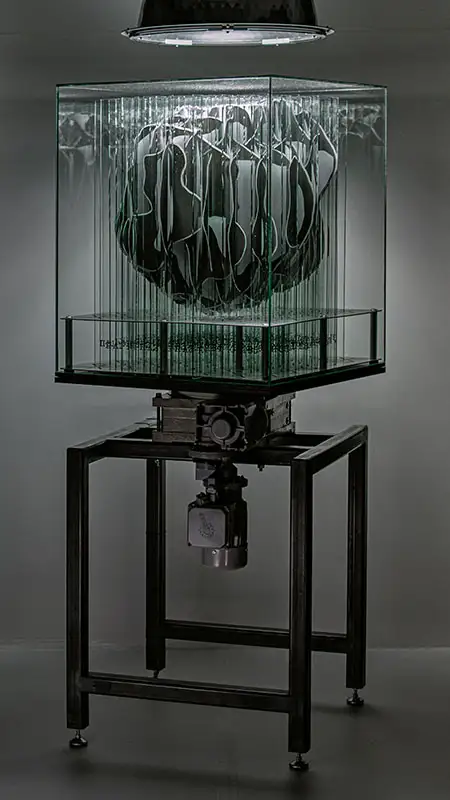

Bonding

Bonding is a central theme in connection with contemporary glass art. Adhesives and glued joints often have to fulfil a wide variety of technical properties, but should usually remain largely invisible. For this reason, there is a wide range of glass adhesives such as one-component and two-component silicones, UV adhesives, various epoxy resins as well as special adhesive tapes and films. In addition to the right choice of adhesive, clean processing is particularly important.

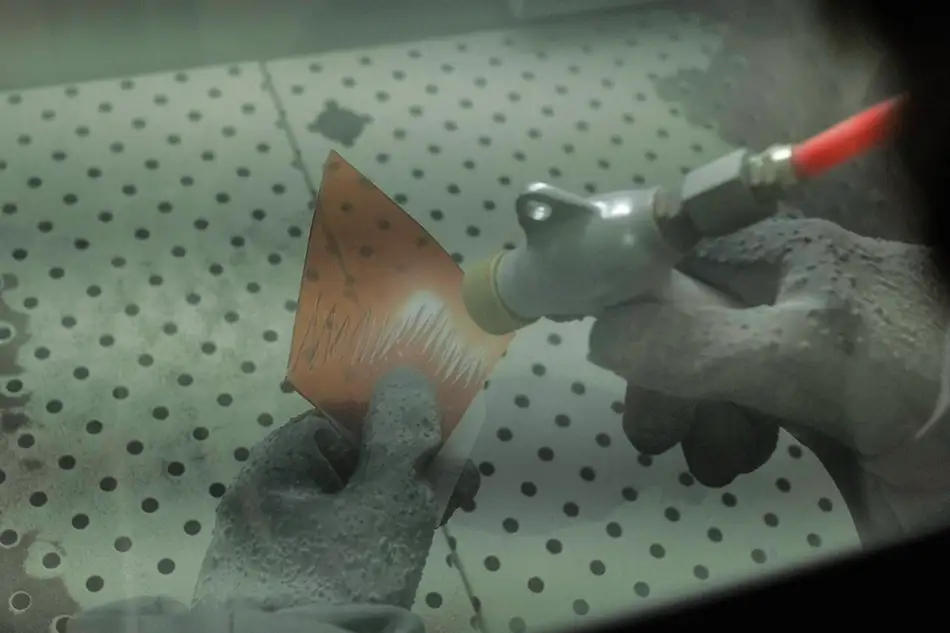

Sand Blasting

By masking and leaving certain areas on the glass free, specific areas can be frosted. The sandblasting technique allows a wide range of applications.

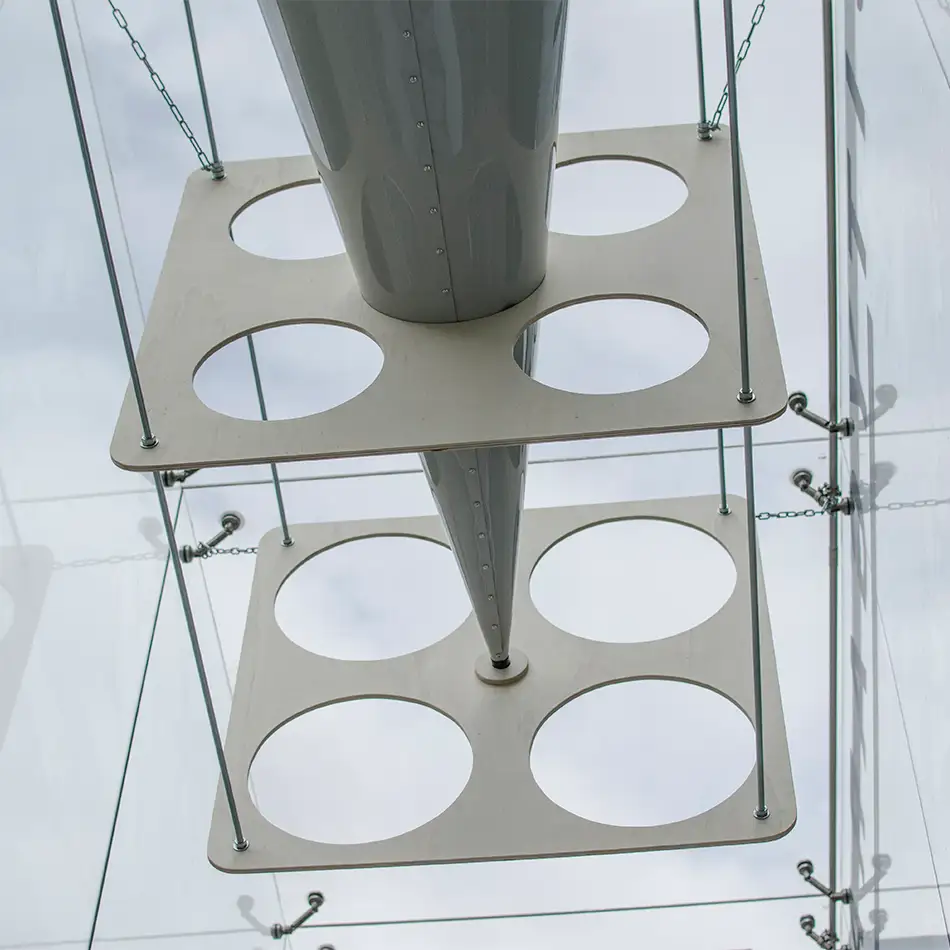

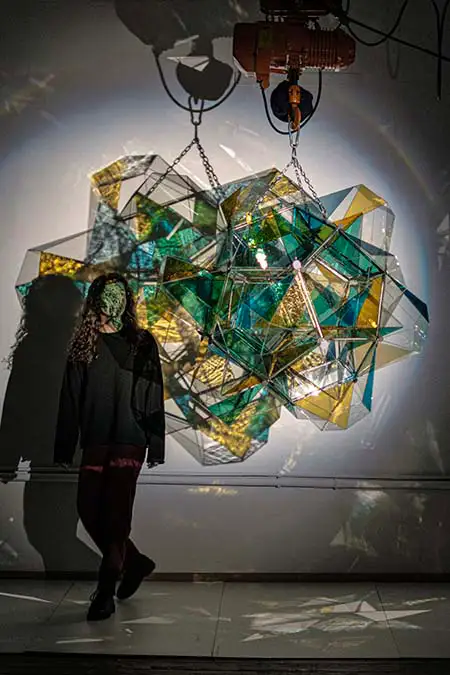

Architectural Glazing

Art in public spaces or artistic works in an architectural context often overlap with the field of architectural glazing, but also with other constructional trades. Thorough research and consultation on technical possibilities and limits as well as on the requirements of standards are essential.